Wheel Building

WheelBuilding

hand built wheels are part science and part art , at first glance a bicycle wheel seems simple, however there are many factors that effect a spoked wheel and levels complexity as each variable comes into play when a wheel is built to achieve a desired outcome.

most production wheels are built on automated wheel building machines, due to stresses involved and design compromises in hubs and spokes so that they can work with the machines these wheels often have much shorter lifespans then when a wheel is hand built with each piece carefully chosen to match intend use of the rider .

We have the right spoke length for any wheel build or repair in stock, thanks to the the Morizumi S.C.T Machine ,

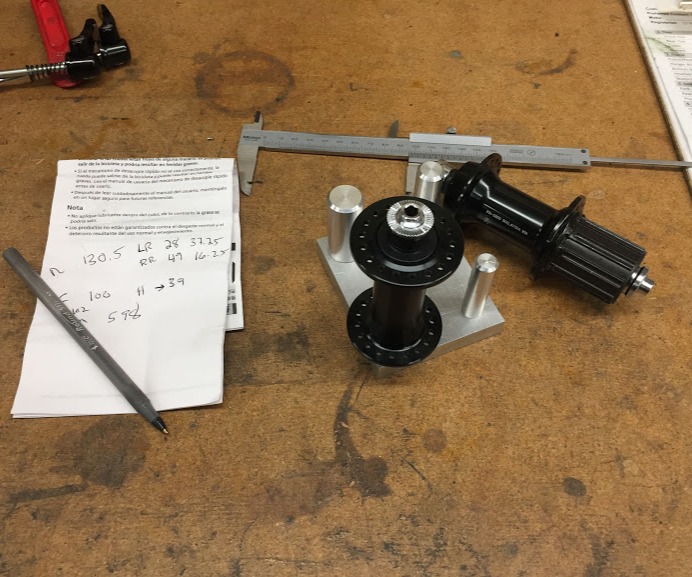

Accurate Measurements

a hard learned lesson of wheelbuilding , Trust nobody's measurements but your own , too often published measurements are not accurate or due to changes from batch to batch of parts may not be right .

the foundation of a good wheelbuild are accurate measurements

Know where the numbers come from

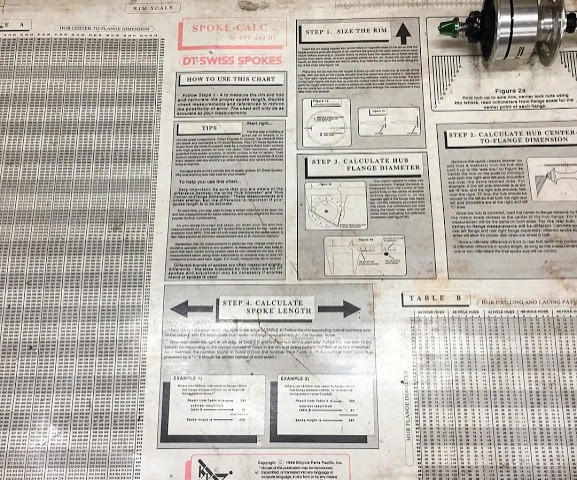

whether you use a DT calculation chart to determine spoke length or an online calculator it's a good idea to understand the general principles of where the number come from .

Fun fact the chart in the photo is the basis of where the online calculators get there numbers.

Handy little tools

a couple of my favorite handy little wheelbuilding tools , the Wheel Fanatyk Nipple Shuffler with it's matching tray , it quickly allows you to get the nipples ready for sticking them on the EVT Mulfinger nipple loader .

Dishing and Spoke Tension

getting the wheel centered on the hub side to side is the what the Dishing instrument is for , the one in photo is a first generation EVT Trigger version , the DT Swiss Tension meter allows measuring accurate tension on the spokes , this way used correctly the tension can be set for the hub and rim specifications along with being balanced for even tension in the wheel.

Truing Stands and Truing wheels

the Truing stand is a workhorse in the shop , we have a number of different stands , the Park TS-4 Professional fits the widest ranges of wheels on the market , this the tool used to hold the wheel while truing and setting spoke tension.

Little Details

just because we can , we like to make sure all the components are matched to the riders use, lace patterns , spokes , nipples are correct for the rider , then we like to make the logo on the hub lines up so you can see it through the valve hole , just shows we were paying attention while building the wheel .

it's a tradition